What is a screwdriver?

This is a hand-operated tool that is used for turning screws that have slotted heads. Some screws have different type slots that are cut across the heads and with a variety of sizes. Some special screws have special shapes and use unique screwdrivers that can fit into the slots. Screwdrivers are usually made of steel and the tips are designed to minimize wear. The handle of the tool is usually made of plastic, metal or wood.

See also:

Most Recognized

The Phillips screwdriver is possibly the most recognized in the world. It seems to be the most used screwdriver that is a part of your toolbox. It is used to fasten screws that are cross point. This is considered to be the most commonly used screws in the industry. There may be times when you experience damaged screws when driving a screw and this is usually found when working on Japanese brand products. These products can be hobby equipment, automobiles, electronic equipment, office equipment, motorcycles, ATVs and so much more.

Who created the Phillips?

The Phillips screwdriver was invited in 1936 by Henry Phillips. The design was an excellent solution to screw tightening as it was made to “cam-out” when a particular torque was reached to prevent an over-tightening of the screw. Another advantage was flat head screws with a Phillips self-centering design allow users to place the driver of the screw into the head quickly and easily.

The American Screw Company was responsible for creating a means of efficiently developing a screw design. They created and patented their design and other screw makers did not back the Phillips concept because it called for an advanced and complex design it required. This was quite distinct from the simple milled slot that was found on the slotted type screw.

The Phillips drive bits can be denoted by the letters PH and a unique size code. These codes increase based on the size and the numerical bit size codes do not necessarily relate to the small screw size numbers. Though the design cam outs as a fail-safe, some quarters criticize it as it can sometimes cam out at a lower than expected torque levels than other crosshead designs.

Japanese Industry Standard (JIS)

The Japanese Industry Standard (JIS) was created as a similar design to the Phillips screwdriver. This design also has a self-centering approach and still allows for quick screwing and driver application. The design of the JIS is that the design allowed users to overtighten and allowed greater torque which would have to be controlled by the user.

Within this context, the main difference between the two tools is that a Phillips screwdriver cannot efficiently be used in JIS screws. It is also good to point out that it can be challenging to see the difference between the two designs without some form of magnification. The JIS screws can be identified with a single dot or a dimple that is found on the top of the screen. This can be challenging to identify with the naked eye if the screw doesn’t have a marking.

Appearance of the Screwdrivers

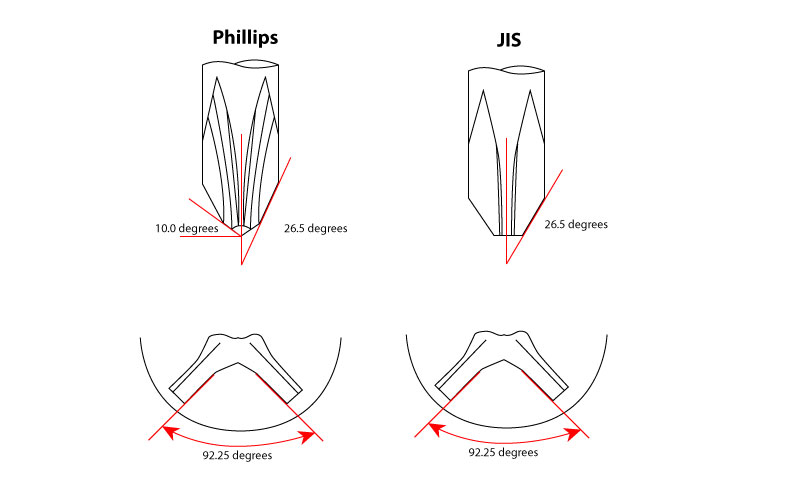

The bottom of the JIS recess is flat and the point of the driver is blunt. The Phillips screwdriver has a similar 26.5-degree cone angle but due to the tapered slots, the pointed tip will not go down full in the screw and will damage the screw if it is forced. If a correctly sized JIS driver is selected it will go down in the full depth and apply without damaging the screw. The JIS screw heads can be easily identified by the user. This can be detected by the X to one side of the cross slot or a single dot.

Benefits of the Design

It is known that the invention of the Phillips screwdrivers was directly related to the assembling of large-scale items such as aircrafts. They wanted to prevent the over-tightening of screws to ensure that the aluminum threads do not strip. The design allows the screwdriver to cam out before this will happen and this is considered a fail-safe.

The Phillips screwdriver is designed with four slots that are cut out of it. Each of these slots was made from the machine processing occurring at right angles. This results in the cross tapering of the arms and it gives rounded corners in the recess of the tool. The fail-safe that prevents the cam out will also prevent the reaming and destruction of the bit.

It can be the same in some areas that the JIS screwdriver is sometimes incorrectly called the Japanese Phillips. It can also be said that many people outside of the Japan region will not know what they are. The confusion or the lack of knowledge of the differences can lead to damage when removing and installing screws with the wrong tool. The JIS will not cam out while the Phillips will. One point to understand, the JIS driver can be used in Phillips screws easily but not vice versa. The drivers are not easily found in the USA but can be possibly found in smaller shops or hobby stores.

Differences

The head of the JIS screwdriver can be identified as it has square edges. When you look at it, it should look like a plus sign. The tip of the screwdriver will also have a sharper point. There are key differences in the design and this allows the JIS cross point screws to offer more torque than the Phillips screw. The Phillips design also looks like a plus sign but the inner corners have more rounding. The tip is also rounded and can be identified this way.

Phillips Screws Strip Easily

One has to be careful as applying too much torque to the Phillips screwdriver may cause it to cam out and strip the head of the screw. This is preferred by people as it will not damage the part you are working out. It is good to note that the same principle is applied when removing a screw that is stuck. You may have a stripped screw caused by a screwdriver that came out of the screw.

Phillips Screwdrivers Strip JIS Screws

The design of a JIS cross-point screw will allow the Phillips screwdriver to be partly inserted into its frame. The contact will only be made with the middle of the screw. If the screw does not become loose when you are driving, this can lead to the screwdriver being forced out. There will not be a lot of contact between them and this can mean that when you are driving the weakest part of the screw head, stripping can occur. Once you keep applying additional pressure, this will give you a completely stripped screw head.

Choosing the right one

When using screwdrivers, it is good to know these differences and how it applies to the work/jobs you are doing. It can be easy to select the wrong tool which leads to damage to the equipment being worked on. Something simple as selecting the wrong tool can lead to the damage of the bigger equipment which can lead to a bigger problem. You would not want this to happen, so it is good to become knowledgeable of these two types of screwdrivers and even other designs that exist.

As noted before, it can also help to know where the item you are working on was manufactured. This can lead you to immediately know which screwdriver you should engage. The rule of thumb is that Japanese designs mostly operate with the JIS model and USA designs will mostly use the Phillips design. This is a key takeaway for readers to understand and look forward to saving your equipment.